Developing Voltage From 4-20mA Current Loops

133

3500 Scarlet Oak Blvd. St. Louis MO USA 63122 V: 636-343-8518 F: 636-343-5119

Web:

http://www.crmagnetics.comE-mail:

sales@crmagnetics.comThe Professional

Energy Monitoring

Company

ISO 9001:2008QualityManagementSystem

M N TI

Applications

H

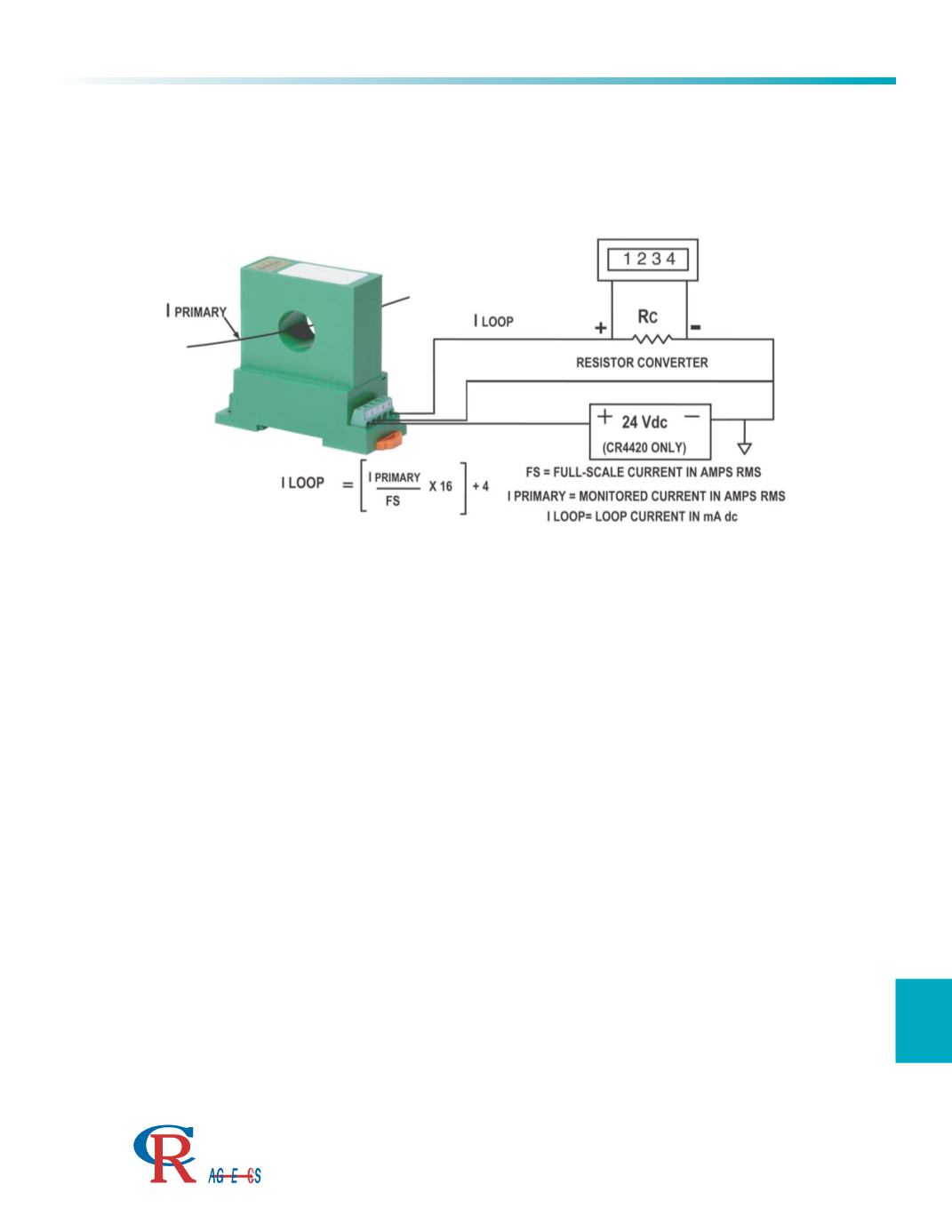

Many of the Analog Transducers from CR Magnetics provide a 4 to 20mA current loop to communicate sensed values.

These loops can be converted to a voltage for input to a wide variety of instrumentation devices including panel

meters, data acquisition systems, and programmable controllers. By adding a precision resistor in series with the

loop, a voltage is developed, which can then be inputted to the instrumentation. In the diagram below, a current

transducer is used to show this concept.

The tolerance of the resistor is critical. Tolerances of the system are additive – using a 0.5% percent transducer in

conjunction with a 1% resistor results in a 1.5% tolerance system.

The temperature coefficient of the resistor is a key factor. All electronic devices exhibit some variance with

temperature. If the resistor has a large variance with temperature, the accuracy of the system will also vary with

temperature. Self-heating of the resistor must also be considered. A typical design of 5VDC at full scale (20mA)

requires a nominal resistance of 250 Ohms (5/.020). The power generated in this resistor at full scale is Volts

times Amps or 5 X .020 = .100 Watts. Choosing a 1/8 Watt (.125) resistor will provide reasonable safety against

destruction, but will cause a significant temperature rise in the resistor. This rise in temperature can result in

significant changes in the value of the resistance. For instrumentation, a resistor with a power rating of at least

10 times the expected full scale power is recommended.

The resistor should be mounted as close as possible to the instrumentation. Once the signal is converted from

current to voltage, voltage drops from wire resistance introduces errors in the signal.

Whenever possible, use similar materials for all wire connections. Galvanic reactions from dissimilar metals can

introduce errors in the readings. An extremely low galvanic reaction such as 5mV introduces a .1% error at 5VDC

full scale. Smaller reading levels results in this error being more significant.