Using the CR4220/60 Series Current Transmitter

136

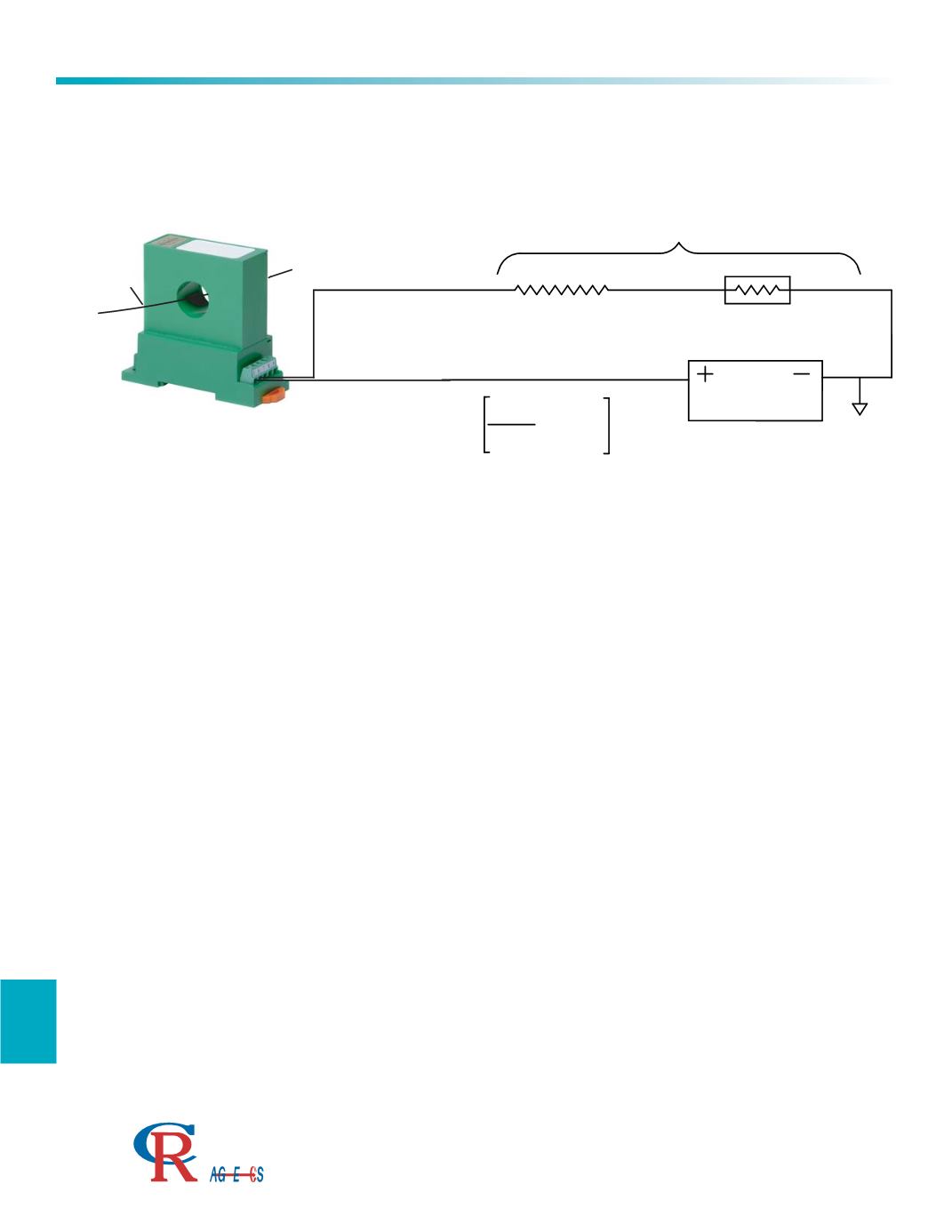

H

+

-

0 to 600 ohms

I

PRIMARY

I

LOOP

=

X 16

24 Vdc

+ 4

FS

INTERCONNECT

RESISTANCE

INSTRUMENTATION

RESISTANCE

I

LOOP

I

PRIMARY

The 4220/60 series are variable resistance devices that automatically adjust their DC series resistance to maintain a

DC current that is proportional to the Average RMS Value of the AC current flowing through the window of the trans-

mitter. Since these are variable resistance devices, the 4-20mA loop must derive power from an external DC power

supply.

Verify that the correct polarity is observed as shown. The 4220/60 series are polarity protected, so damage

should not occur if connected in reverse polarity.

Insure that the total loop resistance (instrument plus wire) does not exceed 600 Ohms. Most commonly, an

instrument with a burden of 250 Ohms is chosen. If the total loop resistance is greater that 600 Ohms the

transducer will not function according to published specifications.

Choosing connection wire with 22 gauge conductors or larger will minimize connection resistance on most

applications. Twisted pair wire should be adequate for most applications but shielded/twisted pair wire with the

shield grounded at the instrumentation end may be required for the most severe environments. Refer to the

instrumentation installation manual for more details regarding interconnect requirements.

Verify that the output of the DC supply is at least 24 VDC, with a current rating of 20 ma or greater per

transmitter connected.

The output is calibrated to be proportional to the Average RMS of the current primary at 60 Hz. Signals from

devices such as SCR and variable speed drives will not produce an accurate indication of RMS current levels.

Multiple loop powered transducers may be attached to the same power supply. Attach one side of the power

supply common to all the transducers.

The first step in troubleshooting would be to check the voltage across all of the components in the loop. At no

load the voltage across the instrumentation will be its burden resistance times .004.

Transducers may be mounted in close proximity to each other without concern for magnetic interaction.

An external current transformer may be attached to the transducer for applications that require monitoring

current levels above 400 AAC.

Applications

3500 Scarlet Oak Blvd. St. Louis MO USA 63122 V: 636-343-8518 F: 636-343-5119

Web:

http://www.crmagnetics.comE-mail:

sales@crmagnetics.comThe Professional

Energy Monitoring

Company

ISO 9001:2008QualityManagementSystem

M N TI